Application

- Vibro-SD piles are well-suited for variable soil conditions as the pile length can be adjusted on-site under the given circumstances.

- The production process of vibro-SD piles is fully automated.

- In floor fields, the designer can opt for a dense pile field combined with a thin floor field with relatively little reinforcement.

- Vroom Funderingstechnieken can provide both the vibro-SD piles for the floor fields and the structural piles for a main support structure.

- Vibro-SD piles are also applicable in ‘mattresses’ for the foundation of roads and terrains.

- In combination with earthwork, settlement-resistant road constructions can be offered.

- In some situations, vibro-SD piles can also be used for structures. However, it should be taken into account that there is a limited possibility to reinforce.

Features

- The pile head is poured up to the working level and finished at the working level to the desired height.

- Pile length can be immediately adjusted to the ground conditions.

- High production speed: a large number of piles per day.

- Suitable for concentric compression loading: larger diameters and limited suitability for eccentric loads.

- The system is low in vibration and noise.

- The system is soil displacing, so no excavated soil.

- Pile system and bearing capacity factors are in accordance with Eurocode 7 (NEN 6743 in-ground formed pile vibrated drawn).

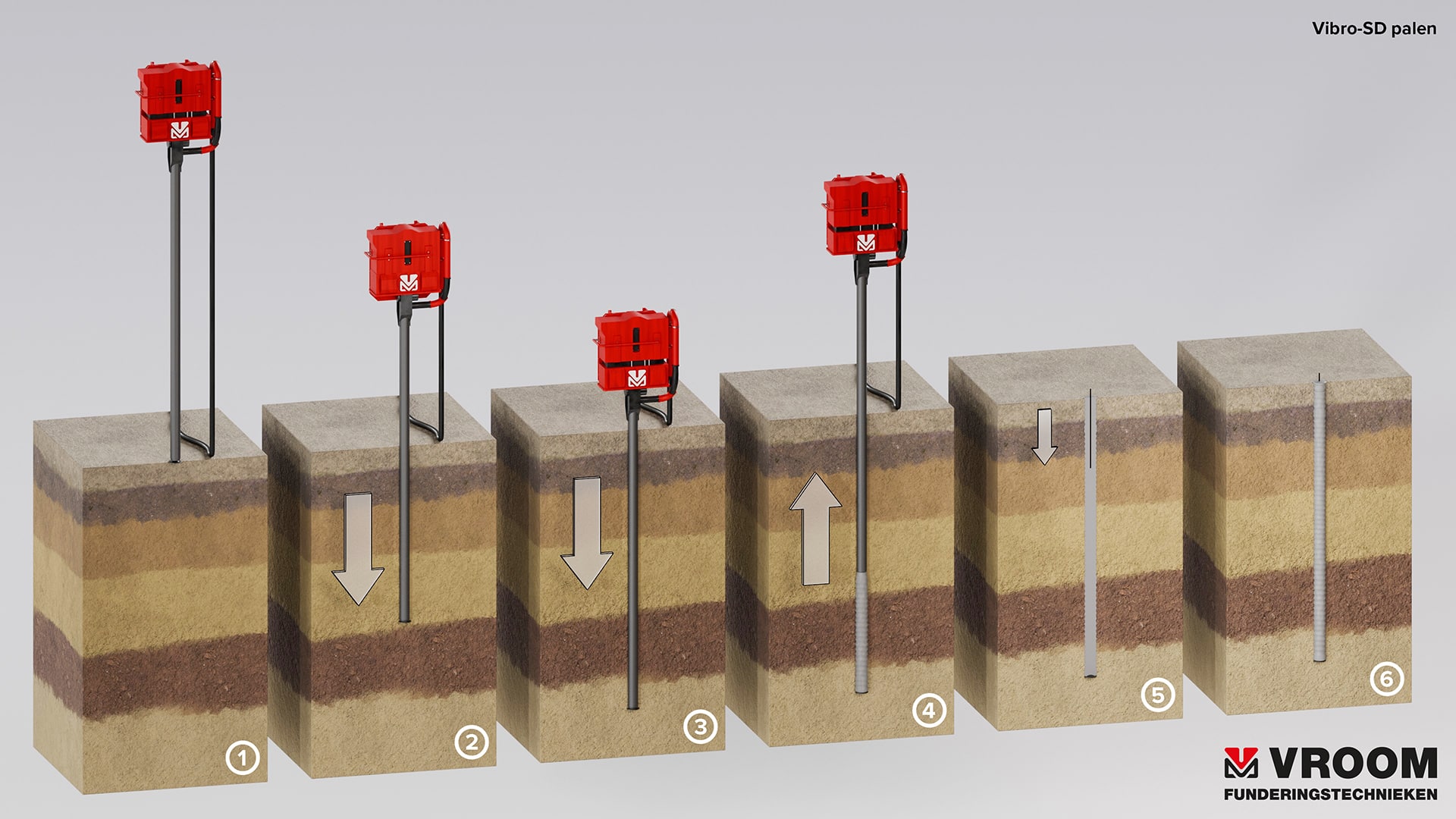

Vibro-SD piles are a cost-effective and logistically interesting addition to traditional and in-ground formed pile systems. The foundation piles are realized at a high production rate. A casing tube is vibrated to depth in the ground. Given the required high production speeds, smaller diameters and lengths are preferred.

For floor fields in industrial halls, a well-thought-out pile plan ensures an even distribution of the floor load.

For larger diameters and pile lengths, or 'construction' piles for a commercial building, other pile systems are available. For floor fields in industrial halls, a well-thought-out pile plan ensures an even distribution of the floor load.

Quality Control

Vroom Funderingstechnieken manufactures vibro-SD piles according to its own execution procedure established as part of internal quality control and nationally applicable standards. Vibro-SD piles produced by Vroom Funderingstechnieken can optionally be acoustically measured and then assessed by an independent advisory bureau. Thanks to its own quality control, appropriate responses can be made in case of doubts about pile quality or client requests regarding execution.

Let Us Advise You

Vroom Funderingstechnieken devotes the utmost care to the creation of our brochures and website. However, no rights can be derived from the content. If you use information from our brochures or our website without verification or further advice from Vroom Funderingstechnieken, you do so at your own risk.

Vroom Funderingstechnieken accepts no liability for the accuracy and/or suitability of the information for the intended application. For questions about the application of our products in concrete projects, we advise you to contact our sales department.